1600pcs/Hr Wire Tinning Machine

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | CHENXIN |

| Certification: | ISO90001 |

| Model Number: | CX-02HR-D |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1/Set |

|---|---|

| Price: | Fob Shenzhen |

| Packaging Details: | wooden case |

| Delivery Time: | 10-15 working days |

| Payment Terms: | T/T |

| Supply Ability: | 150 sets per month |

|

Detail Information |

|||

| Cutting Length: | 15-9,999mm | Adaptable Wire: | Standard Model: AWG#32-AWG#18 (2 Wheels Feeding Wire) Customized Model: AWG#14-AWG#18 (4 Wheels Feeding Wire) |

|---|---|---|---|

| Adaptable Terminal: | 0.3-3.96mm Horizontal, Straight Mold Is Changeable, Adapt To Flag Figure Mold(partially Closed Continuous Plug-in Terminals And Single-grain Terminals Can Be Customized) | Capacity: | 1,400pcs-1,600pcs/hr (with Length 300mm) |

| Stripping Length: | 0-7mm(>7mm Can Be Customized) | Cutting Accuracy: | ±(0.2%*L+1)mm |

| Air Pressure: | 0.5-0.7Mpa(5-7kg/m³) | ||

| Highlight: | 1600pcs/Hr Wire Tinning Machine,1400pcs/Hr Wire Tinning Machine,ISO Automatic Tinning Machine |

||

Product Description

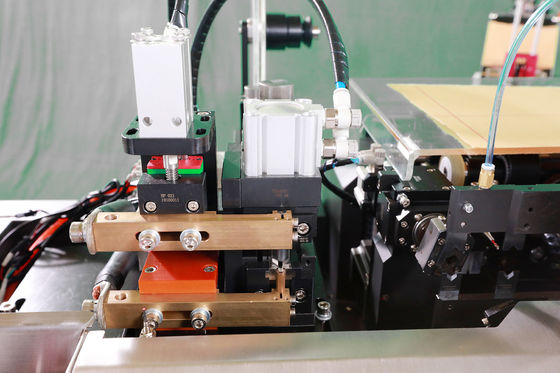

CX-02HR-D Full Automatic Single-end Wire Cable Tinning Nickel Sheets Soldering Machine

Equipment Function:

| Name of the machine | CX-02HR-D Full Automatic Single-end Wire Cable Tinning Nickel sheets Soldering Machine |

| Function |

cutting, single-end stripping, double-end stripping, single-end twisting tinning,single-end crimping single-end nickel sheets soldering(can straight soldering, or left/right soldering) |

| Control Method | HMI+Microcomputer |

| Take-up system | computer automatic pre-feeding device, suitable for coiled wire +reel wire |

| Detection Device | With terminal or not, No wires alarm, air pressure detection |

| Terminal pressure detection system | Optional installation (applicable for domestic and imported systems) |

| Crimping force | 2T Super mute terminal crimping machine |

Technical Parameter

| Voltage | 50/60Hz 220V single-phase |

| Solder voltage | 50/60Hz 380V three-phase |

| Cutting Length | 15mm-9999mm |

| Applicable cable | standard model: AWG#32-AWG#18 (2 wheels feeding wire) Customized model: AWG#14-AWG#18 (4 wheels feeding wire) |

| Applicable terminal | 0.3-3.96mm horizontal, straight mold is changeable, adapt to flag figure mold(partially closed continuous plug-in terminals and single-grain terminals can be customized) |

| Capacity | 1,400pcs-1,600pcs/hr (with length 300mm) |

| Stripping Length | A side 0-6mm; B side 0-8mm |

| Cutting accuracy | ±(0.2%*L+1)mm |

| Air Pressure | 0.5-0.7Mpa(5-7kg/m³) |

| Dimension | 1,210mm*770mm*1,370mm; take-up: 920mm*560mm*1,300mm |

| Weight | about 450kg±15kg; take-up: 80kg |

Device Configuration

| Motor | 3 sets of Japan Mitsubishi servo motors + 4 sets step motors |

| Pneumatic Components | The electromagnetic valve + 9 sets of SMC Cylinder |

| Screw | 2 sets TBI+2 sets of THK module+1 set of KURODA |

| Sensor | Japanese Panasonic |

| Belt | American Gates Brand |

| Bearing | Japnese NSK |

| Blades | t is made of imported alloy steel, processed by slow-moving wire, precision ground, and durable |

![]()

![]()

![]()

Want to Know more details about this product