CX-90 Automatic Wire Cable Binding Twist Tie Machine , Bunching Wire Coiling Machine

Product Details:

| Place of Origin: | China (Mainland) |

| Brand Name: | CX |

| Model Number: | CX-90 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1/Set |

|---|---|

| Price: | EXW, FOB, CIF, C&F |

| Packaging Details: | export standard wooden case |

| Delivery Time: | 5-7 working days |

| Payment Terms: | T/T |

| Supply Ability: | 500sets per month |

|

Detail Information |

|||

| Usage: | Wind And Bind | Winding Range: | 50-200mm(1.97-7.87in) |

|---|---|---|---|

| Binding Shape: | Round, 8 Shape | Length Accuracy: | ±(0.002*L)mm |

| Applicable Wire: | AC Cable ,DC Cable, Data Line, Vedio Cable, Other Electric Wire | Productivity: | 66-75 Times/min |

| Noise Level: | <70dBA | Power Supply: | AC 220/110V/50/60HZ 200W |

| Dimension (L*W*H): | 500*300*400mm | Weight: | 30KG |

| Highlight: | 75 times/min Cable Binding Twist Tie Machine,200W Wire Coiling Machine,Bunching Wire Coiling Machine |

||

Product Description

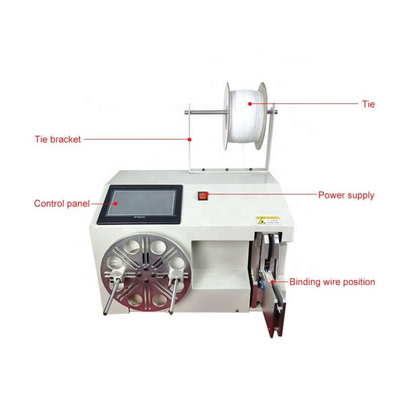

CX-90 Automatic Wire Cable Binding Twist Tie Machine Cable Wire Coiling Bunching Machine

The wire cable binding twisting tie machine with strong points:

- LCD DISPLAY touch screen with fast production setup.

- WINDING PART the shape of finished product can be changed by the adjustment of winding part. Winfing speed is up to 12 times/s.

- TYING PART fast tying speed of 0.7 times/s.

- STEEL WIRE PLACING DEVICE 1,000 meter steel wire will be placed on, which can be used for thousands of times.

Description:

1, This machine is suitable for AC power line, DC power line, USB data line, video line, HDMI HD line and other transmission lines. It is twisted and tied into bundles with rubber coated iron core. It can also be used for other industries that need to be fastened with rubber coated iron core, such as clothes hanger and so on.

2, Employees only need to fix the wire head, use the foot switch to realize winding, take it out and put it at the binding port for automatic binding, and the whole process takes only 4-5 seconds. The machine can set the binding length and the number of winding coils, and can count the output. The machine adopts PLC program control and text display for parameter setting, which is simple and convenient to operate. It can reduce the fatigue intensity of employees, improve work efficiency and save ties.

Technical Parameter

| Model | CX-90-830 | CX-90-1435 | CX-90-4080 |

| Winding inner diameter | 50 - 200 mm | 50 - 250 mm | 50 - 300 mm |

| 65 - 125 mm | 120 - 190 mm | 200 - 350 mm | |

| Tying outer diameter | 8 - 30 mm | 18 - 45 mm | 40 - 80 mm |

| 3 - 28 mm | 15 - 40 mm | 40 - 90 mm | |

| Tying shape | Round, long, 8 shape | Round, long, 8 shape | Round, long, 8 shape |

| Winding speed | 66 - 75 circles/min | 66 - 75 circles/min | 66 - 75 circles/min |

| Noise level | < 70 dB(A) | < 70 dB(A) | < 70 dB(A) |

| Power supply | 110, 220 V (50 - 60 Hz) | 110, 220 V (50 - 60 Hz) | 110, 220 V (50 - 60 Hz) |

| Operation interface | Bilingual | Bilingual | Bilingual |

| Dimension | 500 * 300 * 400 mm | 500 * 300 * 400 mm | 500 * 300 * 400 mm |

| Weight | 40 kg | 52 kg | 65 kg |

![]()

![]()