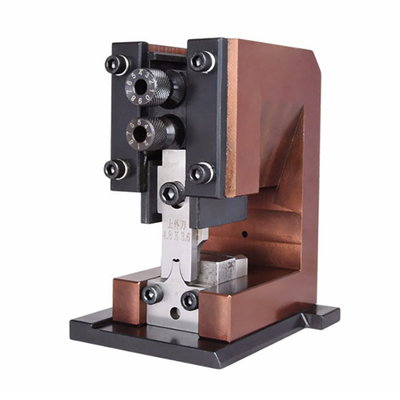

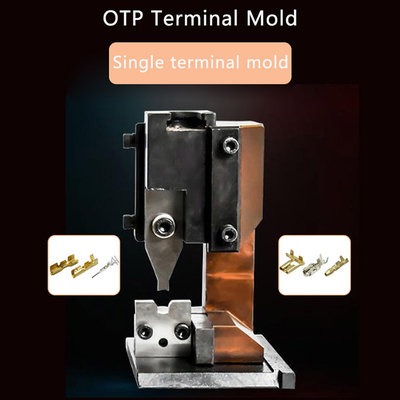

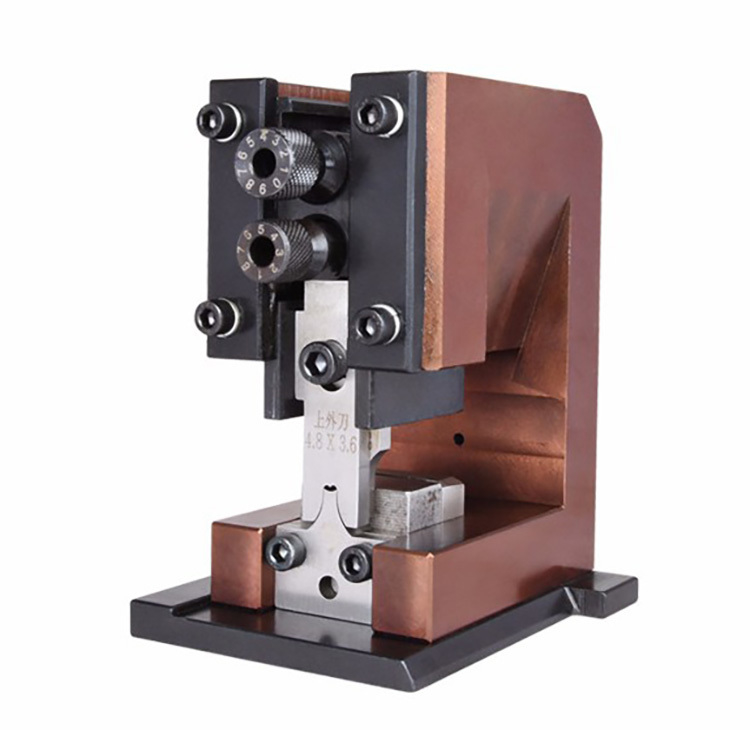

Terminal Crimping Applicator,Non-insulated Terminales Single Brass Battery Terminal Lugs Pression Stamping Mould

Product Details:

| Place of Origin: | Guangdong, China |

| Model Number: | terminal crimping mould |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|

|

Detail Information |

|||

| Usage: | Terminal Crimping | Product Name: | Terminal Crimping Mold |

|---|---|---|---|

| Custom Processing: | Yes | Operating Voltage: | 220 (V) |

| Mould Material: | Metal | Pressing Force: | 150 (kgs) |

| Weight: | 4.5 (kg) | Specifications: | OTP Single/OTP Horizontal/ Straight/ U-shaped/flag Mold Etc |

| Application: | Terminal Machine | ||

| Highlight: | 220V Operating Voltage Terminal Crimping Applicator,4.5 kg Weight Terminal Crimping Applicator,200 SPM Punching Terminal Crimping Applicator |

||

Product Description

Terminal Crimping Applicator, Non-insulated Terminales Single Brass Battery Terminal Lugs Pression Stamping Mould

Product Specifications

| Product Name | terminal crimping mold |

|---|---|

| Type | different type terminal |

| Custom | yes |

Key Features

- Best price for terminal mould manufacturer in China

- Used for processing more than 1 various products punching, widely used in mobile, tooling, commodity, and other industry production

- Works with high speed press machine (punching SPM more than 200, production times 10 per day)

- Eliminates shape deviation when multiple dies and presses work simultaneously by using general dies and presses for large quantity production

- Better guarantees product quality while reducing facility and factory space requirements

- Saves more than 10% material

- Uses coil material and automatic feeder for production, greatly reducing labor intensity and saving labor cost

- Different models can be designed according to clients' product shape, size, pattern, and other requirements

Product Images

Want to Know more details about this product