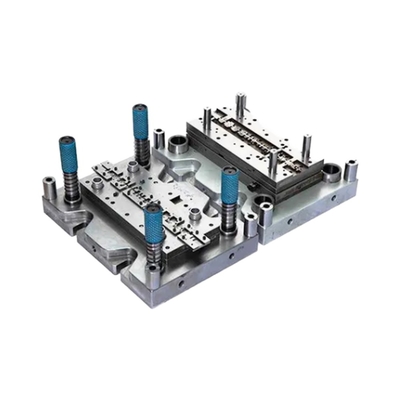

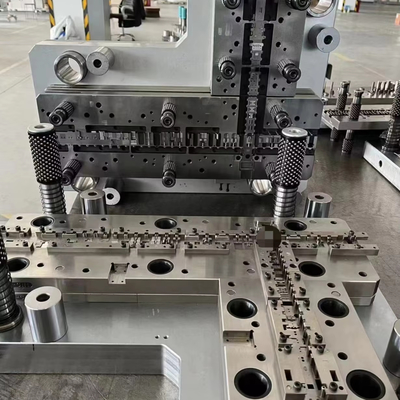

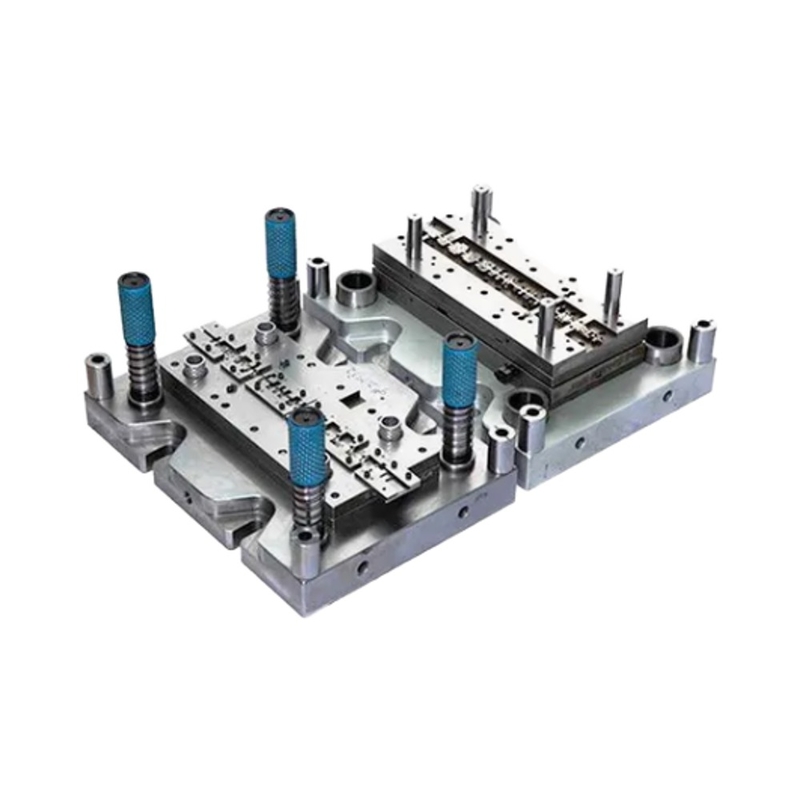

Metal Terminal Crimping Mold with Punching SPM 200 and Save Material 10% for High Speed Press Machine

Product Details:

| Place of Origin: | Guangdong, China |

| Model Number: | terminal moulds |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|

|

Detail Information |

|||

| Shaping Mode: | Punching Mold | Product Material: | Metal |

|---|---|---|---|

| Product: | Terminal Connector Moulds | Product Name: | Terminal Crimping Mold |

| Custom Processing: | Yes | Operating Voltage: | 220 (V) |

| Mould Material: | Metal | Pressing Force: | 150 (kgs) |

| Weight: | 4.5 (kg) | Specifications: | OTP Single/OTP Horizontal/ Straight/ U-shaped/flag Mold Etc |

| Application: | Terminal Machine | ||

| Highlight: | Metal Terminal Crimping Mold,Punching SPM 200 Terminal Die Stamping Mold,Save Material 10% Terminal Connector Moulds |

||

Product Description

OEM Terminal Die Stamping Mold Metal Moulds Product Category

Product Specifications

| Product Name | Terminal Crimping Mold |

|---|---|

| Type | Different Type Terminal |

| Custom | Yes |

Key Features

- Best price for terminal mould manufacturer in China

- Designed for processing multiple products with punching operations

- Widely used in mobile, tooling, commodity, and other industrial production

- Compatible with high-speed press machines (200+ SPM)

- Production capacity of 10 times per day

- Eliminates shape deviation in mass production

- Reduces facility and factory space requirements

- Saves over 10% material consumption

- Works with coil material and automatic feeder to reduce labor intensity and costs

- Custom designs available for different shapes, sizes, and patterns

Our terminal crimping molds guarantee product quality while reducing production costs and space requirements, making them ideal for high-volume manufacturing.

Product Images

Want to Know more details about this product