Double End 3.96mm Wire Terminal Crimping Machine Full Auto High Precision

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | CHENXIN |

| Certification: | ISO90001 |

| Model Number: | CX-01D |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1/Set |

|---|---|

| Price: | Fob Shenzhen |

| Packaging Details: | wooden case |

| Delivery Time: | 10-15 working days |

| Payment Terms: | T/T |

| Supply Ability: | 150 sets per month |

|

Detail Information |

|||

| Automation: | Full Auto | Applicable Cable: | Standard Model: AWG#20-AWG#32(2 Wheels Feeding) Custom Model: AWG#18-AWG#14(4 Wheels Feeding) |

|---|---|---|---|

| Adaptable Terminal: | 0.8-3.96mm | Cutting Length: | 13mm(total Length)-9999mm |

| Highlight: | 3.96mm Wire Terminal Crimping Machine,ISO90001 Wire Terminal Crimping Machine,High Precision auto crimping machine |

||

Product Description

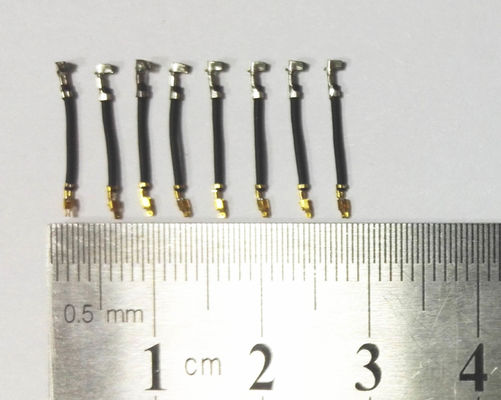

CX-01D Full Automatic High Precision Wire Double End Terminal Crimping Machine

Features:

1. Fully automatic double end crimping machine is specially designed for ultra-fine wires and high-precision wires. The wire cutting, stripping, and Crimping are more precise and stable.

2. The double-head terminal machine adopts Japan's Mitsubishi servo and Taiwan's Hi Win screw, which are precisely matched to ensure mechanical precision, efficiency, and stability.

3. Full computer touch screen operation, the input of cutting length, stripping, half-stripping and twisting, and other parameters can be set completed at one time, reducing the adjustment time, no need for professional operation, and the adjustment is simpler and more convenient.

4. The computer automatically detects mechanical failures and displays the cause of the failure, which facilitates rapid troubleshooting and greatly improves production efficiency.

Equipment Function:

| Name of the machine | CX-01D Full Automatic Double-ends Terminal Crimping Machine |

| Function | A side, B side Cutting, Stripping, Crimping |

| Control Method | HMI+Microcomputer |

| Take up system | Computer automatic pre-feeding device, suitable for no-shaft coiling wire + with-shaft coiling wire |

| Detection Device | With terminal or not, No wires alarm, air pressure detection |

| Terminal pressure detection system | Optional installation (applicable for domestic and imported systems) |

| Defective product handling | Sorting (cutting device can be installed) |

| Adaptable mold | OTP standard horizontal mold, straight mold, flag figure mold, European and Korean molds can be customized |

| Crimping force | 2T/3T Super Mute terminal crimping machine |

Technical Parameter

| Voltage | 50/60Hz 220V single phase |

| Cutting Length | 13mm(total length)-9999mm |

| Applicable cable | standard model: AWG#20-AWG#32(2 wheels feeding) Custom model: AWG#18-AWG#14(4 wheels feeding) |

| adaptable terminal | The pitch is 0.8-3.96mm and part of the closed-end continuous terminal and single terminal can be customized |

| Capacity | 3200pcs-3800pcs/hr (with length 13mm-200mm) Actual production efficiency varies according to wire and processing technology, subject to actual conditions |

| Stripping Length | A side 0-6mm; B side 0-10mm |

| Cutting accuracy | ±(0.2%*L+1)mm |

| Air Pressure | 0.5-0.7Mpa(5-7kg/m³) |

| Dimension | 1,400*800*1,550mm take-up 920*560*1300mm |

| Weight | about 450kg±15 take-up 80kg |

Device Configuration

| Motor | Mitsubishi/INOVANCE |

| Pneumatic Components | 6sets of SMC Cylinder+8 regulating devices and 8 SMC solenoid valves. |

| Screw | 4 sets TBI |

| Sensor | Japanese Panasonic |

| Belt | American Gates Brand |

| Bearing | Japnese NSK |

| Blades | t is made of imported alloy steel, processed by slow-moving wire, precision ground, and durable |

![]()

![]()