USB2.0 / Type C / Micro / Data Wire Production Soldering Welding Machine 2000W

Product Details:

| Place of Origin: | China (Mainland) |

| Brand Name: | CHENXIN |

| Certification: | ISO9001 |

| Model Number: | CX-TypeC901V14E |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1/Set |

|---|---|

| Price: | FOB, EX-WORK, C&F, CIF |

| Packaging Details: | wooden case |

| Delivery Time: | 15-20 working days |

| Payment Terms: | T/T |

| Supply Ability: | 150/sets per month |

|

Detail Information |

|||

| Power: | 2000W | Voltage&frequency: | AC 220v 50Hz |

|---|---|---|---|

| Air Pressure: | 5 ~ 6kgf / C ㎡ | UPH Value: | 1000-1200pcs / H |

| Weight: | 400kg | Dimension: | 2267mm L × 915mm W × 1366mm H |

| Highlight: | USB2.0 Data Wire Soldering Welding Machine,Soldering Welding Machine 2000W,USB2.0 Data Wire Soldering Welder |

||

Product Description

USB2 0/TYPE. C / Micro / Data Wire Production Automatic Soldering Welding Machine

Product introduction

The tin dipping welding machine invented by our company is used for products with tin dipping welding, including wire clamping, pre cutting, peeling, tin dipping, welding and other stations. Compared with manual operation, the efficiency is improved by 4-6 times, reducing personnel training time, avoiding manual operation, poor quality stability, debugging, single operation and continuous operation.

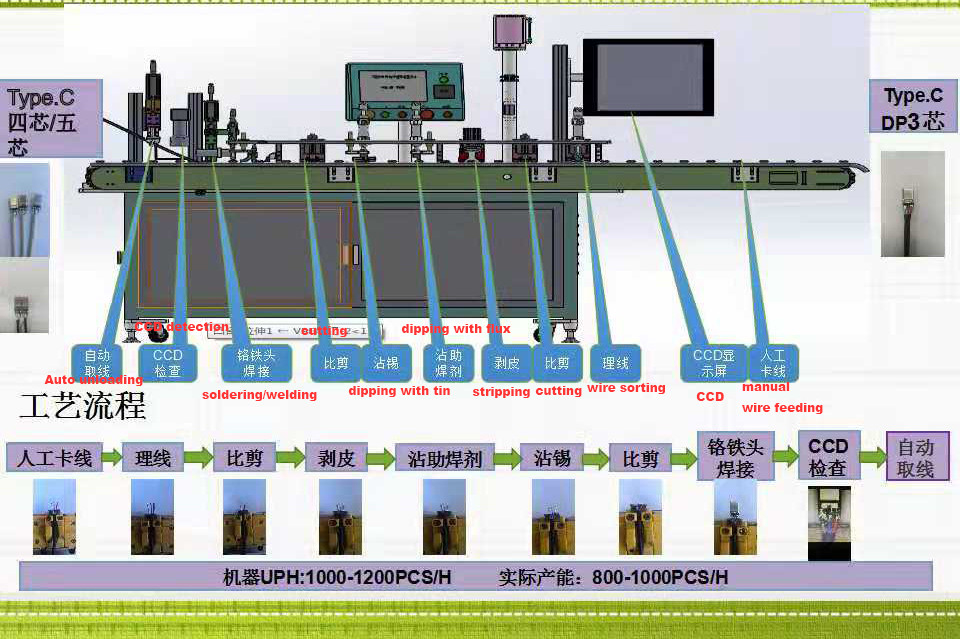

Product process

Manual wire clamping →wire sorting →cutting →peeling →dipping with flux →dipping with tin →cutting →welding/soldering →CCD inspection →automatic wire taking

Equipment parameters

Power supply: AC220V

Power: 2000W

Air pressure: 5 ~ 6kgf / C ㎡

Weight: 400kg

Volume: 2267mm long × 915mm wide × 1366mm high

UPH value: 1000-1200pcs / h

Product features

1: An automatic tin dipping welding machine with two operators can produce 8000pcs to 10000pcs in 10h, which is equivalent to two people completing the work of 3-5 people

Quantity, more importantly, it is easy to train employees to work, the quality is reliable, and reduce the production difficulty of the next process to ensure product consistency;

2: The process of automatic completion of the equipment: manual wire clamping - Inductor induction - peeling - tin dipping - Welding - automatic wire taking;

3: Applicable product type of equipment: USB2 0/TYPE. C / micro / data wire auto soldering.

![]()