CX-JY02 Six Station Inner Automatic Stator Winding Machine 0.4-0.75Mpa

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | CHENXIN |

| Certification: | ISO-9001 |

| Model Number: | CX-JY02 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SET |

|---|---|

| Packaging Details: | carton/wooden packages 1100*1500*1600mm |

| Delivery Time: | 35 working days |

| Payment Terms: | L/C, T/T |

|

Detail Information |

|||

| Power Supply Standard: | In Line With China's Power Supply Standard Power Supply 380V ± 10% | Air Source Pressure: | 0.4-0.75Mpa |

|---|---|---|---|

| Ambient Temperature: | - 5°C---40°C | Applicable Wire Diameter Of The Machine: | ¢0.1-0.6 "Need To Replace The Tensioner" |

| Stator Outer Diameter: | ¢20-100mm | Stator Inner Diameter: | ¢10-80mm |

| Highlight: | 0.75Mpa Automatic Stator Winding Machine,Inner Automatic Stator Winding Machine,Six Station Automatic Stator Winder |

||

Product Description

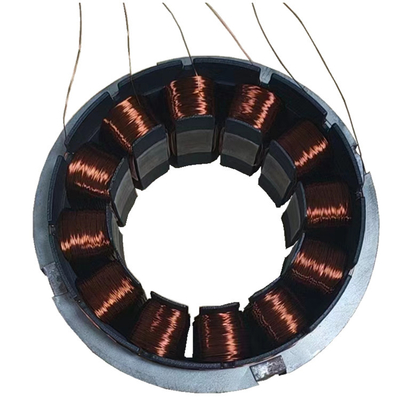

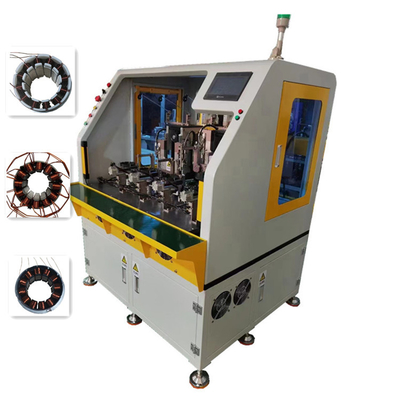

CX-JY02 Automatic Stator Six-Station Inner Winding Machine

The main performance parameters of the equipment:

1. The scope of equipment applicable products: fan motors, air conditioner motors, range hood motors, servo motors, stepper motors and various

DC brushless motor, etc.

Equipment parameters and product accuracy that can be met:

Six-station model: the machine can control and process the winding process while winding at high speed, and can perform four-axis synchronous and neatly arranged winding, and can achieve special processes with high winding requirements; the machine adopts servo precision Positioning, automatic thread winding, thread tail, automatic winding, automatic cable arrangement, automatic indexing, automatic clamping and cutting, realize the optimal cost performance of the equipment.

Applicable wire diameter of the machine: ¢0.1-0.6 "Need to replace the tensioner"

Stator outer diameter: ¢20-100mm

Stator inner diameter:¢10-80mm

Stator thickness:¢4-85mm

Equipment speed: 600-1000 rpm "according to the stator height wire diameter"

3. Equipment size: 1100*1500*1600mm

2. Brand requirements for main components of the equipment

Equipment main components and Brand

| Part Name | Brand Model / Specification | Origin Country | Remark |

| Cylinder Air | TAC | Taiwan | |

| Control System | Leisai | Shenzhen China | |

| Touch Screen | Weilun | Taiwan | |

| Motor | Keiyo | China | Custom |

| Rack | Aluminum Profile Rack | China | |

| Lead Screw | SHAR | Taiwan | |

| Guide rail | Shangyin | Taiwan | |

| Spare Parts | Keiyo | China |

The equipment is suitable for grid power supply/working environment

Power supply standard: in line with China's power supply standard power supply 380V ± 10%

Air source pressure: 0.4-0.75Mpa

Remarks: The electrical box (electrical control box) of the machine should be equipped with a leakage protection switch and safety measures. The equipment circuit is manufactured according to the equipment standardization, and the wiring diagram is attached for maintenance.

Ambient temperature: - 5°C---40°C

Equipment schematic diagram

![]()

Information

1) The equipment is accompanied by a detailed equipment instruction manual.

2) The following information should be attached to the equipment manual:

a. Equipment operation manual

b. Equipment daily maintenance manual electrical and mechanical systems

c. A list of wearing parts, which should include: the name, brand, model specification, quantity used, etc. of components, as well as the processing drawings and purchase of wearing parts.

Equipment commissioning, acceptance and training

1. After the equipment arrives at the factory, Party B assists Party A in installation and commissioning, and Party B shall bear the expenses during the installation and commissioning process by itself;

2. After the equipment debugging is completed, the performance and requirements of the equipment shall be checked and accepted by both parties in accordance with the technical agreement;

3. Equipment acceptance shall be checked and accepted at Party A's factory, and the product samples provided by Party A shall be used for trial production to meet Party A's process quality and use requirements;

4. Party B's company will assign operators to Party A's company for personnel operation training (the training period is up to 2 days).

Seven, equipment after-sales service

1. After the equipment commissioning is completed, the engineers of Party B shall conduct equipment operation and maintenance training for the technical and operating personnel of Party A;

2. After being notified of the failure of Party A's equipment, Party A shall provide an oral or written solution within 2 hours to guide Party A's engineering personnel to solve the failure. If the failure cannot be eliminated, Party B's engineer shall go to Party A's company for equipment repair. For maintenance, Party B needs to try to solve the problem in the shortest time (the time shall not exceed 48H, except holidays), so as to reduce the loss of Party A.